CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

103

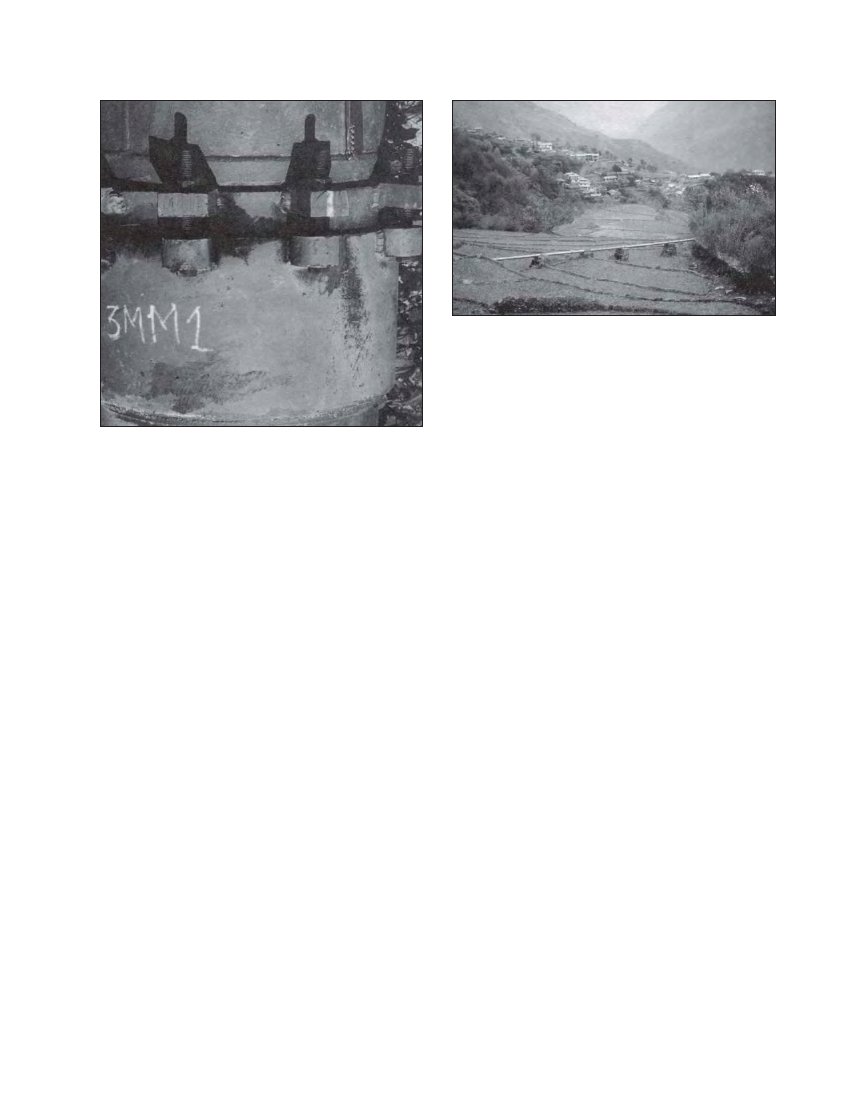

Photo 6.14 Penstock at Ghandruk with village in the background

Photo 6.13 Sliding expansion joint, Jhankre mini-hydro

The following coats of paint are recommended:

Outside surface of above ground mild steel pipes

First two coats of primer should be applied on the pipe surface.

Red Oxide Zinc Chromate primer is appropriate for this purpose.

Then another two coats of high quality polyurethane enamel

paint should be applied on top of the primer.

Outside surface pipe of which will be buried or cast into

anchor blocks

Two coats of primer similar to above ground pipe should be

applied. Then, another two coats of high-build bituminous

paint should be applied over the primer. Provide an extra coat

of bituminous paint at transition areas, which are more prone

to corrosion (see Figure 7.1).

Inside surface of pipes

For small diameter pipes it may not be possible to paint the

inside surface. However whenever possible, the inside surface

should be painted with two coats of good quality red lead

primer. If there is a doubt about the quality of paint, the

supplier’s specifications should be checked prior to its use.

Note that paintwork is not required for HDPE or PVC pipes.

Any paintwork damaged during transport and installation

must be made good, so that the full number of coats is present

everywhere. This is especially important for buried pipes.

6.12 Installation

The following procedure should be used:

The centreline of the penstock should be set out using a

cord and pegs along the selected route as shown in Figure

6.8. For micro-hydro schemes above 20 kW of installed

capacity, a theodolite should also be used to ensure that

the bend angles correspond to the fabricated pipe bends.

A line should be marked by spreading lime on the surface

of the ground to replace the cord. Then the positions of

anchor blocks and support piers should be marked to the

required spacing for exposed pipes and excavation carried

out along this line as required.

For buried pipes, the penstock is installed in the excavated

trench and backfilled as shown in Figure 4.8. The backfill

should be rammed in layers and a slight hump above the

level of the ground helps to keep the alignment dry. An

improperly backfilled penstock alignment can quickly become

the route for drainage water down the hillside. However,

note that backfill should be completed only after the pipe

has been pressure tested.

For exposed pipes, the anchors and supports should be

constructed as will be discussed in Chapter 7. The pipe

should be cast into the anchors and placed on one support

pier at a time. No further supports or anchors should be

built until the pipe is secured to the previous anchor block

or support pier. For both site welded and flange connected

pipes, the end should protrude from the last support block

with adequate margin (~ 300 mm) so that either the flange

or the weld line does not lie on the support pier during

thermal expansion or contraction. If more than one pipe

section needs to be welded between the support piers,

temporary supports should be used as shown in Photograph

6.15. Flange connected pipes should be joined and the

bolts tightened as the installation progresses.

The installation of the penstock should start from the

machine foundation and proceed upstream. This avoids

any misalignment between the penstock and the turbine

housing. Since the turbine needs to be firmly fixed to

the machine foundation, there is almost no tolerance at

this end after the machine foundation has been

constructed. Furthermore, the pipe sections below the

expansion joints can slide down if installation proceeds

downstream from the forebay. Minor pipe deviation can

be adjusted at the forebay wall, but such adjustment is